Waste management facilities are valuable assets that need to be managed efficiently: Large, continuously increasing volumes of waste, often consisting of hazardous materials, are constantly moved between storage boxes and processing facilities – around the clock. At the same time, compliance with regulations and requirements for storage and reporting must be ensured while at the same time operating profitably. That is no easy task.

Most recently, thermal waste incineration has been included in the German emissions trading system as a result of amendments to the Fuel Emissions Trading Act (BEHG), which came into effect on January 1, 2024. This means that waste incinerators are now required to purchase certificates for every ton of CO2 emitted during waste incineration, currently priced at 45 euros per ton. The cost is expected to continue increasing.

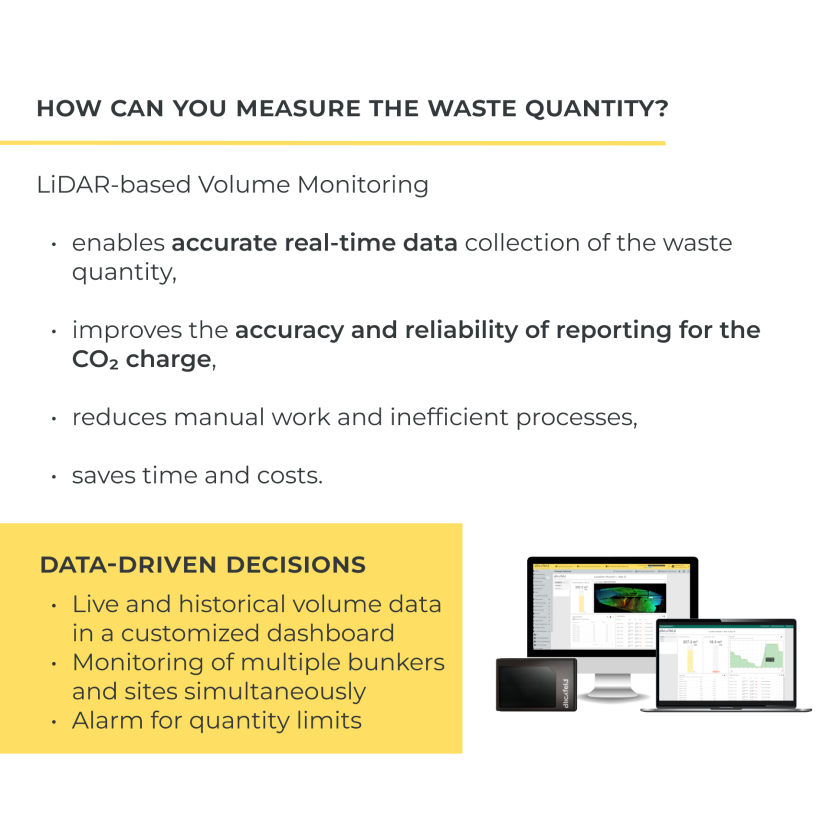

A key success factor for this reporting is access to reliable real-time data on waste volumes in the plants. So far, however, this has been missing across the board, as many companies rely on inaccurate data collected using methods such as eyeballing or weighbridges. In a recent expert talk, Allan Kane, Managing Director of Quvo Ltd. and expert for waste management and recycling technology, and Florian Petit, co-founder and CXO of Blickfeld, discussed in detail how this challenge can be solved

The highlighted serval key takeaways:

- LiDAR-based Volume Monitoring enables accurate inventory accounting creating transparency for dispatch and processing planning thanks to 3D volume measurement of waste stockpiles.

- Real-time inventory data allows timely decision-making, preventing revenue losses by anticipating production and process interruptions.

- Digitization of waste inventory recording reduces manual work and inefficient processes, saves time and costs, and improves the accuracy and reliability of data.

In this on-demand expert talk, companies will gain valuable insights into how waste management companies can automate their processes and bring their warehouse management into the digital age. Accessible at any time, it is a convenient way to learn more about the benefits of efficient waste management with LiDAR.

About the experts

Allan Kane

Director of Quvo Ltd.

Before founding Quvo in 2022, Allan worked in the material processing and waste management sectors for some 15 years. Initially working in the machinery supply within these sectors, Allan has also held a board-level position with one of the UK’s largest waste management companies, giving him a broad knowledge of the creation, monetary value, and operational importance of stockpile management.

More about Quvo Ltd.

Florian Petit

Co-founder and Chief Experience Officer of Blickfeld

Before founding Blickfeld, Dr sc Florian Petit worked on the control of robots as part of scientific work at the Technical University of Munich, Stanford University, the German Aerospace Center (DLR), and ETH Zurich. The roboticist obtained his Ph.D. in the field of human-machine collaboration.

With a strategic view of the developments in the target industries, Florian works as Chief Experience Officer with various partners and customers to realize projects across multiple industries.